In the modern food industry, milk production lines are a highly specialized field involving a complex array of equipment and processes. This article will detail the main equipment and processes of a milk production line and show you how we can provide you with quality equipment and customized solutions.

Milk production line Main equipment

- Milking equipment

Milking equipment is the starting point of a milk production line and consists of the milking machine, milking pipeline and cleaning system. The milking machine ensures that the milk is extracted from the cow in comfortable and hygienic conditions, while avoiding harm to the cow. - Storage and transportation equipment

Storage tanks and transportation vehicles are essential to ensure that the milk remains fresh and of good quality during the production process. These need to be insulated and cooled to prevent milk spoilage. - Purification and separation equipment

Purification equipment is used to remove impurities such as hair and dust from the milk. Separation equipment is used to separate milk into fat and skim milk. - Homogenizing and Pasteurizing Equipment

Homogenizing equipment is used to make the milk more uniform in texture through high pressure treatment, while pasteurizing equipment is used to kill harmful microorganisms in the milk to prolong the shelf life. - Filling and Packaging Equipment

Filling equipment fills processed milk into a variety of containers, such as glass bottles, plastic bottles and cartons. Packaging equipment adds labels, caps, etc. to the product so that it meets market requirements.

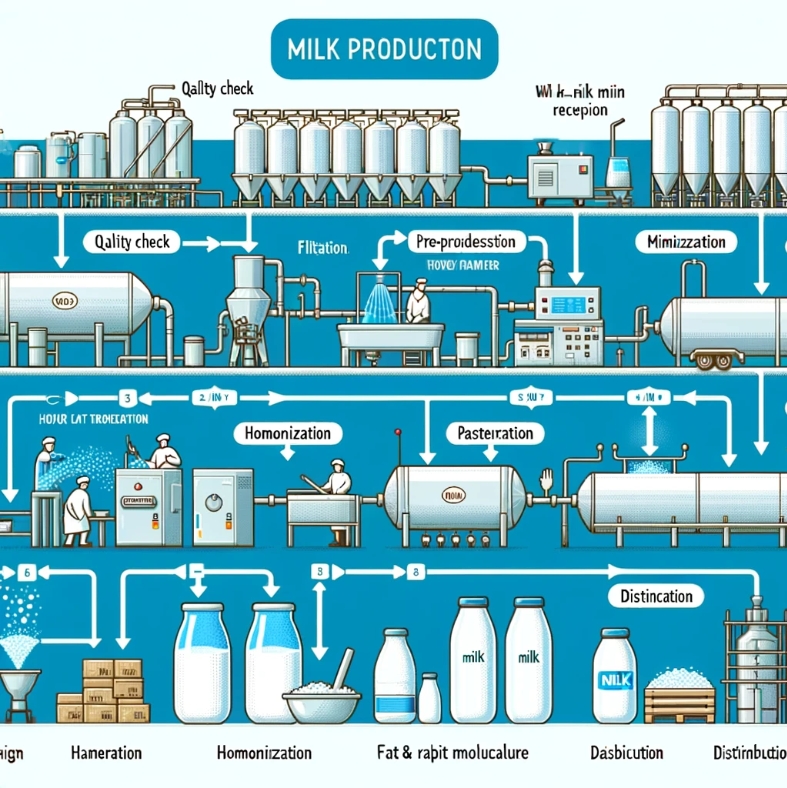

Milk production line process flow

The process of milk production line includes: milking, storage and transportation, purification and separation, homogenization and pasteurization, filling and packaging. These steps must follow strict hygiene standards to ensure the quality and safety of the final product.

Our Services

We have a wealth of experience and expertise to provide you with the following services:

- Milk Equipment for sale: We offer a wide range of high-quality milk production line equipment, including milking machines, storage tanks, purification equipment, homogenization equipment and so on. These equipment are subject to strict quality control to ensure performance and reliability. Our professional sales team will provide you with the most suitable equipment solution for your specific needs.

- Equipment Customization: We understand that each customer’s production needs are unique, so we offer comprehensive equipment customization services. From design to manufacturing, we will work closely with you to ensure that the customized equipment fully meets your production requirements.

- Technical Support: We offer a range of technical support services including installation, commissioning and operator training. Our team of professional engineers will ensure the smooth operation of your production line and provide continuous maintenance and upgrade services.

- After-sales service: We value the satisfaction of each and every customer and therefore provide comprehensive after-sales service. Whether it’s equipment failure or performance optimization, we will respond and provide solutions in a timely manner.

In short, we are committed to providing you with the best quality milk production line equipment and services. By working with us, you can be assured of efficient, reliable and hygienic production equipment that adds value to your milk production business. Please feel free to contact us and let’s work together to create a superior milk production line!