With the development of the food industry, consumer demand for food safety and quality is increasing. Pasteurized milk, with its unique taste and nutritional value, is loved by consumers. In order to meet the market demand, the equipment and technology of pasteurized milk production line is also progressing. In this article, we will introduce the equipment and process of pasteurized milk production line in detail, as well as the quality solutions we can provide.

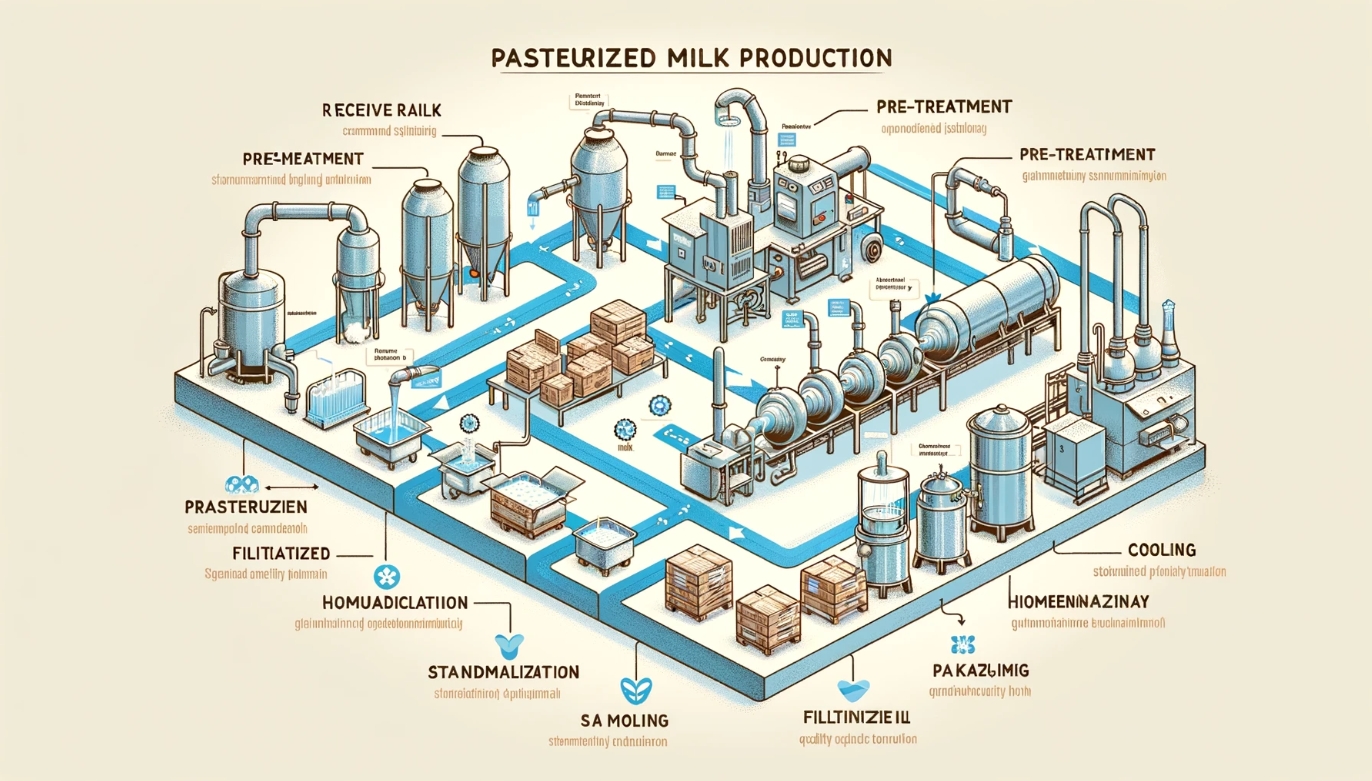

Pasteurized milk production lines Required equipment

- Milk storage tank: used to collect and store raw milk to ensure the quality of raw milk.

- Filtration system: to remove impurities and microorganisms in milk, improve the purity of milk.

- Homogenizer: breaks up the fat globules in the milk to make the milk taste more delicate.

- Pasteurizer: effectively kills the harmful microorganisms in the milk by heating it to a certain temperature and holding it for a certain period of time to ensure the quality of the product.

- Milk Cooling system: quickly cools the pasteurized milk to a suitable temperature for further processing.

- Filling equipment: Fill the cooled milk according to specifications to ensure sealing and product hygiene.

- Testing equipment: tests the milk during the production process for various indices to ensure that the product quality meets the standard.

Pasteurized milk production lines Process flow

Raw milk collection and storage: Collect fresh raw milk in the storage tank and store it for processing.

- Filtration: Remove impurities and microorganisms from the milk through the filtration system.

- Homogenization: Milk is homogenized using a homogenizer to improve flavor.

- Pasteurization: Milk is heated to a specific temperature and pasteurized to kill harmful microorganisms.

- Cooling: Pasteurized milk is rapidly cooled to the appropriate temperature by a cooling system.

- Filling and sealing: The cooled milk is filled and sealed using filling equipment.

- Testing and packaging: The finished milk is tested using testing equipment and packaged after passing the test.

Our advantages and solutions

We are committed to providing customers with high quality solutions for pasteurized milk production line.

As a professional equipment manufacturer, we have many years of experience and technology accumulation, and we can customize the production line equipment according to customers’ needs and provide perfect after-sales service.

Our advantages are

- Excellent equipment quality: We adopt advanced production technology and high-quality raw materials to ensure the stability and durability of the equipment.

- Strong customization capability: We can customize suitable production line equipment for customers according to their actual needs and production scale.

- Perfect after-sales service: We provide one-stop services such as equipment installation, commissioning, training, etc. to ensure that customers can start production smoothly. At the same time, we also provide regular maintenance and troubleshooting services to ensure the stable operation of the production line.

- Continuous innovation and R&D: We constantly invest in research and development and are committed to promoting the technological innovation of pasteurized milk production line to meet the changing needs of the market.

In addition to equipment sales, we also provide installation, training and maintenance services to ensure the smooth operation of your pasteurized milk production line. Our commitment to customer satisfaction is unparalleled, and we strive to build long-term partnerships with our customers.

If you are in the market for pasteurized milk production equipment or are looking to upgrade your existing line, look no further. Contact us today to learn more about our products and services and let us help you take your milk production to the next level.