With the growing concern for a healthy diet, the market demand for plant-based protein beverages continues to grow.

Among them, soy milk has been welcomed worldwide as a nutritious and easily digestible beverage.

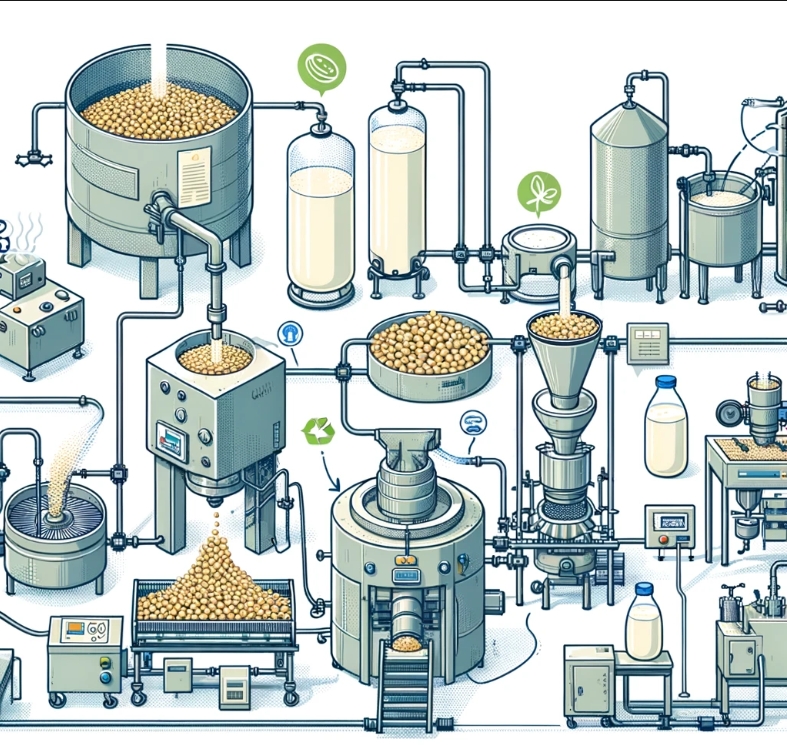

To meet this market demand, an improved soy milk production line is being developed.

Soy milk production line equipment required

- Cleaning equipment: Used to clean soybeans, remove impurities and dust.

- Soaking equipment: Soaks the cleaned soybeans in water to soften them for subsequent grinding.

- Grinding equipment: Grinds the soaked soybeans into fine soy milk.

- Separation equipment: Separates the soybean residue and soy milk from the soy milk to obtain pure soy milk.

- Cooking equipment: Heats the soy milk to a suitable temperature to eliminate anti-nutritional factors and improve the taste.

- Homogenizing equipment: Homogenize the soy milk under high pressure to make it more delicate in taste.

- Sterilization equipment: Ensure the safety and shelf life of soy milk through high-temperature instant sterilization or ultra-high-temperature sterilization technology.

- Filling equipment: Filling the sterilized soy milk into various specifications of packaging containers.

- Testing equipment: quality testing of soy milk after filling to ensure that the product meets the relevant standards.

Soy milk production process

- Soybean cleaning: remove impurities and dust.

- Soaking: soften soybeans to facilitate grinding.

- Grinding: grind soybeans into fine soy milk.

- Separation: removing the dregs to obtain pure soy milk.

- Cooking: Heating the soy milk to eliminate anti-nutritional factors and improve flavor.

- Homogenization: High-pressure homogenization treatment to make the taste more delicate.

- Sterilization: To ensure the safety and shelf life of soy milk.

- Bottling: Filling soy milk into different sizes of packaging containers.

- Testing: Quality testing of filled soy milk to ensure product quality.

Our advantages and services

With years of experience in designing, manufacturing and installing soy milk production lines, we can provide you with a one-stop solution. From equipment selection and process design to installation and commissioning, we provide professional guidance and quality service. In addition, we can also customize your exclusive soy milk production line according to your actual needs to meet the requirements of different production capacity, quality and market positioning.

- Equipment Customization: We can customize soy milk production line equipment with different specifications and capacities according to customers’ specific needs to ensure that customers’ actual production needs are met.

- Process Optimization: With rich experience and technical strength, we can optimize and improve the soy milk production process to enhance production efficiency and product quality.

- Installation and Commissioning: We will send a professional technical team to provide customers with equipment installation, commissioning, and training services to ensure that the production line is put into operation smoothly.

- After-sales service: We provide a perfect after-sales service system, including equipment maintenance, troubleshooting, and technical support, etc., to ensure the stable operation of customers’ production lines.

In a word, we will provide you with high quality soy milk production line equipment and professional technical services to help you stand out in the competitive market. If you have any questions or needs, please feel free to contact us, we will be glad to serve you!